Single Transducer Merges Bio-Implantable Magnetic and Piezo Harvesting

What you’ll learn:

- Why dual-source harvesting offers benefits for powering implantable devices.

- How the dual-source harvester was constructed, along with its operating principles.

- The results achieved with this device at various energy-capture levels.

As implantable medical devices shrink in size—which eases their internal placement and reduces discomfort—they also create an increasing challenge of providing even the minuscule DC power that’s required to operate. While a battery could be used, battery size has a lower limit and would need eventual replacement, which risks infection.

An attractive alternative that’s been explored is energy harvesting of various sources (magnetic, thermal, vibration, ultrasound). However, harvesting effectiveness is generally proportional to size and capture area, so smaller devices argue against that solution.

Dual-Energy-Source Harvesting Device

Recognizing this problem, a team at the Pennsylvania State University has developed a single device that can simultaneously harvest energy from magnetic fields and ultrasound sources. Note that this isn’t a dual-transducer scheme with their outputs in parallel. They maintain it’s the first device to harvest these dual-energy sources simultaneously with high efficiency and operate within the strict thermal, magnetic, and other safety limits for human tissue.

The devices use a two-step process to convert magnetic-field energy to electricity. One layer is magnetostrictive, which converts a magnetic field into stress. The other is piezoelectric; it converts stress, or vibrations, into an electric field. The piezoelectric layer also can simultaneously convert ultrasound energy into an electric current. The combination enables the device to turn a magnetic field into an electric current.

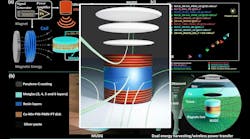

Their newly designed magnetoelectric device with disk architecture is comprised of a high energy-density, novel MnO2 and CuO co-doped Pb(In,Nb)O3–Pb(Mg,Nb)O3–PbTiO3 (PIN–PMN–PT) piezoelectric disk-shaped transducer sandwiched between magnetostrictive Metglas layers (Fig. 1).

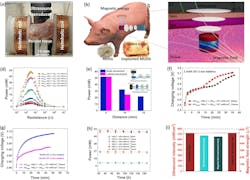

1. (a) The overview of the present study related to magnetic- and ultrasound-energy-based dual energy harvesting and storage in a battery (inset shows the real image of the MUDG). (b) Schematic representation of the MUDG device for dual (magnetic field and ultrasound) energy harvesting with the description of each component. (c) The comparison of the power density of the MUDG5 device with the other published technologies. (d) For the proof-of-concept experiments, the MUDG is implanted inside the porcine tissue and wirelessly powered through magnetic field and ultrasound energies simultaneously.

The magnetic field and ultrasound-induced dual generator (MUDG) produces an ultra-high rms power of ∼52.1 mW with a power density of ∼597 mW/cm3 at an ∼500 μT magnetic field and 675 mW/cm2 ultrasound intensity.

Results demonstrate that the MUDG can overcome the limitations of traditional wireless power-transfer systems for human body application, providing a novel platform with the advantages of ultra-high-power density, small size, biocompatibility, and tolerance to angular misalignment. Testing and evaluation were done for magnetic-field harvesting, ultrasound-energy harvesting, and combined harvesting.

Magnetic-Field Energy Harvesting for Medical Devices

The magnetoelectric device operates through a two-step process for transforming an AC magnetic field into an electric field (direct magnetoelectric effect) or vice versa. Initially, the input magnetic field induces a strain (S) in the magnetostrictive layers through magnetostriction. This strain is then transmitted to the piezoelectric layer via elastic coupling. Subsequently, mechanical stress (T) emerges in the piezoelectric layer due to elastic stiffness, leading to the creation of surface charge density (D) or polarization through the direct piezoelectric effect.

This charge separation generates an output voltage or electric field within the piezoelectric layer. The deformation in the piezoelectric layer generates electric charges from the MUDG device through the direct piezoelectric effect. The use of a radial-mode disk-shaped piezoelectric layer has an unprecedented advantage for its tolerance to angular misalignment, offering a higher surface area that’s suitable for ultrasound conversion.

The working mechanism of the MUDG device uses the principle of direct magnetoelectric and piezoelectric effects occurring in different steps under the application of magnetic field and ultrasound, respectively.

In the initial stage, when neither magnetic field nor ultrasound is present, the MUDG device doesn’t produce any electrical charge. However, when a magnetic field is applied, the ME device (which includes a piezoelectric layer) experiences stress and generates electrical charge through the direct magnetoelectric effect, resulting in electricity generation.

When ultrasound pressure is additionally applied along with the magnetic field, the ME device experiences even greater stress in the piezoelectric material, which generates additional electrical charge and, consequently, higher electrical output voltage.

As the piezoelectric layers compress under the combined influence of the magnetic field and ultrasound pressure, electrons flow from one electrode to another through an external circuit, causing the ME device to produce a positive signal. Similarly, when the piezoelectric layer expands or decompresses, electrons flow in the opposite direction through the external circuit, generating a negative signal.

In the absence of ultrasound and solely under the influence of a magnetic field, the ME device produces a relatively low output voltage due to reduced stress in the piezoelectric layer. Finally, in the absence of ultrasound and magnetic field, the ME device can’t generate any output signal because no stress is generated in the piezoelectric layer.

Ultrasound Energy Harvesting Usage in Medical Implants

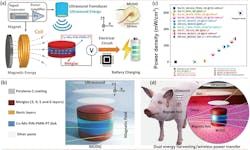

To evaluate the output performance of the MUDG devices, they were subjected to ultrasound pressure using a commercial transducer, and output was measured in water to mimic the soft tissue at 5- and 15-mm distances (Fig. 2). A custom-designed 3D-printed holder was used to hold the MUDGs/transducers and prevent any misalignment. The MUDG devices, powered by the ultrasound energy, were evaluated by measuring their output signals across a broad frequency range of 220 to 260 kHz.

2. (a) Measurement setup for a magnetic-ultrasound dual energy harvester and (b) illustration scheme for dual energy harvesting under water. (c) The generated output voltage from the MUDG devices using individual magnetic field/ultrasound and combined (magnetic and ultrasound) technologies (inset shows the zoomed graph). (d) and (e) Generation of output power in MUDG devices varying with external resistance under a 200-μT magnetic field and at 137 mW/cm2 ultrasound intensity, respectively. (f) The generated power varying with external load resistance under simultaneous magnetic-field and ultrasound energy stimulation. (g) and (h) Generated power variation with external resistance of MUDG devices under a 500-μT magnetic field and at 675 mW/cm2 ultrasound intensity, respectively. (i) The generated power variation with external load resistance for MUDG devices under a 500-μT magnetic field and at 675 mW/cm2 ultrasound intensity based on simultaneous measurement.

The performance at the resonance frequency of the MUDG devices was verified by adjusting a similar ultrasound intensity level, which was done by changing electrical power applied to the transducer. To assess the impact of the ultrasound-induced piezoelectric effect, COMSOL simulations were used covering solid mechanics, transient pressure acoustics, and electrostatics. For this simulation, the airspace was changed to water, and a uniform background pressure field with 10 kPa was applied and the pressure calculated.

Magnetic-Field and Ultrasound Simultaneous Energy Harvesting

To evaluate the dual energy-harvesting capability of MUDG devices under magnetic field and ultrasound stimulation, either individually or concurrently, a continuous sinusoidal mode with infinite cycles was used. Water was used as the medium to measure the performance of dual energy harvesting since it has no impact on magnetic fields and has acoustic impedance similar to that of human tissue, particularly for ultrasound.

Performance Evaluation of the MUDG Device

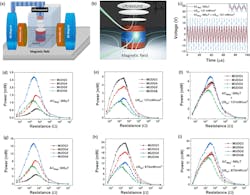

The power density of the MUDG device is an important property for practical applications, which can be determined at different input magnetic fields/ultrasound intensities (Fig. 3). At a lower magnetic field (100 μT) and ultrasound intensity (137 mW/cm2), MUDG3 (third version) shows a higher power density due to the predominance of ultrasound over the magnetoelectric effect in comparison to MUDG5 (their fifth version). However, MUDG5 can harvest a highest power density of ∼596 mW/cm2 under simultaneous power-transfer conditions when operating closer to the imposed safety limit.

3. (a) The average rms power density of the MUDG devices under different magnetic fields and ultrasound intensities. (b) Charging capability of the MUDG5 device for 1-, 4.4-, and 10-mF capacitors under a 100-μT magnetic field. (c) The charging performance of the MUDG5 device for a 1-farad supercapacitor. (d) and (e) The 1-, 11-, and 30-mA-hr Li-ion battery charging characteristics using the MUDG5 device under dual magnetic field and ultrasound stimulation with or without the transformer. (f) Demonstration of LED lighting through combination of a bridge rectifier and the MUDG5 device under a 200-μT magnetic field or at 137-mW/cm2 ultrasound intensity and the associated circuit diagram.

To demonstrate the practical utility of the MUDG5 device, capacitors, supercapacitors, and batteries were charged by connecting it to a full-wave bridge rectifier to convert the AC to DC. The MUDG5 device can rapidly charging capacitors under different conditions.

For example, when subjected to a 100-μT magnetic field, the device can charge a 1-mF capacitor to 5.6 V within 1 minute, a 4.4-mF capacitor to 5.5 V within 4 minutes, and a 10-mF capacitor to 5.0 V within 6.5 minutes. When exposed to a higher magnetic field of 300 μT, the device can charge a 10-mF capacitor to 9.76 V in 6.36 minutes.

Going ”Live”—Literally

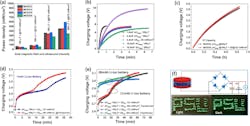

An ex vivo study of porcine tissue was carried out to validate the implantability of MUDG5 for dual energy harvesting under a 22- × 40-mm2 area with different thicknesses (5, 10 and 15 mm) tissue (Fig. 4). (Ex vivo refers to a medical procedure in which an organ, cells, or tissue are taken from a living body for a treatment or procedure, and then returned to the living body.)

4. (a) Image of the implanted MUDG5 device in 5-mm porcine tissue to demonstrate dual energy harvesting. (b) Schematic of the ex vivo porcine tissue and the possible location of implanted MUDG5 for implantable device realization. (c) Illustration of dual energy harvesting from MUDG in porcine tissue. (d) Power output of the MUDG5 device under simultaneous energy harvesting varying with external load resistance. (e) Power output of MUDG5 in 5-, 10-, and 15-mm-thick porcine tissue under a 500-μT magnetic field and at 675-mW/cm2 ultrasound intensity. (f) and (g) 1- and 3-mA-hr 3-V Li-ion battery recharging characteristics in water and porcine tissue during simultaneous energy harvesting. (h) The stability of performances of the MUDG5 device measured in tissue for consecutive 170 h. (i) The standard safety level and the measured safety level presented for both magnetic field and ultrasound intensity.

The MUDG5 device can generate a high output power of ∼52.17 mW in porcine tissue under a 500-μT magnetic field and at 675-mW/cm2 ultrasound intensity. The output power of the MUDG5 device drops to 22 mW at 15-mm thickness in porcine tissue, primarily due to the device's lower ultrasound pressure and increased damping of tissue that restricts its vibration. The MUDG5 device can recharge the 1-mAh Li-ion battery up to 3.11 V within 35 min. with a 1.78X faster rate in tissue compared to water (3.06 V within 36 min.). The faster charging rate in the tissue medium is attributed to the more concentrated magnetic-field strength compared to that in the water medium.

Ensuring Medical Safety in the Harvesting Devices

The team analyzed and followed the latest safety guidelines from the FDA and other relevant organizations. They considered the safety limits for AC and DC magnetic field strengths, which are in the range of ≤550 μT and ≤1670 Oe according to the IEEE standard. Hence, the individual and combined technologies have no harmful effects under a 500-μT magnetic field.

The measured ultrasound intensity for the MUDG5 device is 675 mW/cm2, which is below the safety threshold and, hence, no harmful effect occurs at the applied ultrasound intensity. The mechanical index (MI) is an important standard parameter to detect the mechanical damage that usually happens due to the thermal/mechanical effects coming from the side effects during the propagation of ultrasound waves through organisms. The calculated MI for MUDG5 is 1.3, which is well below the FDA-approved safety limit of 1.9 for general ultrasound-diagnostic systems.

The work is described in detail in their highly readable paper “Magnetic field and ultrasound induced simultaneous wireless energy harvesting,” published in the journal Energy and Environmental Science from the Royal Society of Chemistry. There’s also a detailed Supplementary Information file that provides additional analysis and discussion.