Wind Turbines and Stormy Weather: Mitigating Disaster

What you’ll learn:

- Insight into wind turbine technologies and how they deal with extreme weather.

- Turbine safety features that help mitigate damage.

- What the future holds for wind turbine technology.

Wind turbines in the U.S. and its territories number more than 70,000 and generate about 151 GW of power, or enough juice to serve the equivalent of 46 million American homes. It’s also currently the fourth largest producer of electricity in the U.S., with most turbines concentrated in the center of the country. While the number of wind turbines continues to escalate, their numbers are coming under threat from a natural foe—extreme weather.

According to the EPA, storm activity in the Atlantic Ocean and Gulf of Mexico has increased over the past 30 years. Storm intensity is closely related to variations in sea surface temperature in the tropical Atlantic and has risen noticeably during that time.

The same can be said for tornadoes, which have been increasing in outbreaks, and not in the traditional “Tornado Alley” of the Great Plains, but rather in the Southeast’s “Dixie Alley.” These often accompany severe storms, with both damaging almost everything in their paths.

Damage to Wind Turbines and How to Withstand It

While wind turbines harness the strength of the wind, they do face challenges when storms strike, testing the limits of their design and the resilience of renewable-energy infrastructure. Turbines are generally designed to handle high winds and harsh weather conditions on both land and sea. Still, extreme storms can sometimes cause significant damage.

According to a 2019 study from the Journal of Wind Engineering and Industrial Aerodynamics, between 2007 and 2017, there were 1,479 wind turbine accidents around the globe, 33 of which were weather-related. There are recent examples of wind turbines being damaged by weather, including MidAmerican Energy’s Orient wind farm near Greenfield, Iowa, where a tornado felled five towers after wind speeds reached 100 mph.

Though wind turbines can be damaged by extreme weather, the damage is often isolated. That means if turbines go down, the electrical grid is mostly unaffected, making it easier to replace them after the fact. Some turbines look like they could be easily damaged, but they’re typically built to withstand high winds. They have a number of safety features that help mitigate damage during extreme events, especially those located in areas known for harsh weather events.

Wind Turbine Safety Features

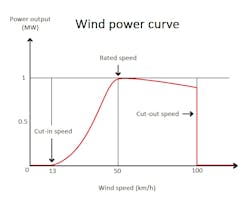

Most wind turbines are outfitted with a cut-in speed and a cut-out speed, meaning they need a minimum wind speed to start rotating the blades, and will only operate within a certain maximum speed. When that threshold is exceeded, the turbine will be disengaged—the blades will move into a position that doesn’t generate lift and then lock itself using onboard brakes. It resembles propeller aircraft that rotate the propellers to certain degrees to maximize or minimize thrust.

Most of today’s wind turbines must be built to withstand sustained winds of 112 mph and peak 3-second gusts of 156 mph, according to IEC (International Electrotechnical Commission) standards. It’s easy to think that more wind speed would equal more power generated, making excess speed a good thing. That’s not necessarily the case, though, as wind turbines must be protected to remain functional and efficient. To get a better understanding of how turbines respond to detrimental weather conditions, we need to look at their power curve.

What is the Wind Turbine Power Curve?

The power curve (see figure) outlines a wind turbine's cut-in speed. In other words, it’s the amount of wind speed needed for the turbine blades to begin to rotate and start generating power, which is typically in the 6- to 9-mph range.

As the wind speed increases, more power is generated until it reaches a certain limit, otherwise known as rated speed—a point where the turbine reaches maximum power generation. If the wind speed continues to climb, the power generated remains constant until the turbine reaches a cut-off speed and begins to shut down to prevent strain on the rotor.

Each wind turbine is outfitted with an anemometer, a sensor that measures wind speeds and direction. When that sensor measures wind speeds in excess of 55 mph, it triggers the turbine to automatically shut down, even though most turbines are rated to handle much greater speeds. These safety features reduce the risk of turbine damage during extreme weather.

Feathering the Blades

Another wind turbine safety feature to handle excessive wind speeds is known as “feathering the blades” or pointing them into the wind to reduce their surface area. Propeller-based aircraft also use this feature to increase their angle of pitch to be parallel to the airflow. It helps reduce damage to the blades and ensures the turbine will continue to generate power efficiently.

Regardless of the destructive wind speeds, the yaw drive located in the turbine’s nacelle will continue to point the rotor toward the wind, even if it shifts direction. Once the wind has slowed to the threshold cut-off or below, the blades unfeather or unlock, and normal operation resumes.

Other Wind Turbine Safety Measures

Modern weather forecasting techniques have lengthened warning times considerably. Forecasters can typically issue warnings one to seven hours in advance regarding conditions that favor tornadoes or high wind speeds. This allows technicians to provide a level of protection to turbines and the electrical grid that might become affected in those areas. And new nacelle designs also help increase resilience and durability against extreme weather conditions and remain operational after the threat has passed.

Improved materials, new aerodynamic shapes, autonomous breaking features, and the latest weather-monitoring techniques all contribute to the safety of wind turbines and their power-generating efficiency. As the latest technologies become available, newer turbine designs will continue to increase their durability and power generation in the years and decades to come.

About the Author

Cabe Atwell

Technology Editor, Electronic Design

Cabe is a Technology Editor for Electronic Design.

Engineer, Machinist, Maker, Writer. A graduate Electrical Engineer actively plying his expertise in the industry and at his company, Gunhead. When not designing/building, he creates a steady torrent of projects and content in the media world. Many of his projects and articles are online at element14 & SolidSmack, industry-focused work at EETimes & EDN, and offbeat articles at Make Magazine. Currently, you can find him hosting webinars and contributing to Electronic Design and Machine Design.

Cabe is an electrical engineer, design consultant and author with 25 years’ experience. His most recent book is “Essential 555 IC: Design, Configure, and Create Clever Circuits”

Cabe writes the Engineering on Friday blog on Electronic Design.