Optimize Power-Supply Performance with a High-Accuracy Window Monitor

What you'll learn:

- Different tolerances involved with power-supply design and monitoring.

- Operation of window voltage supervisors.

- The importance of threshold accuracy.

With the demand for portable and battery-operated gadgets and devices rapidly ramping up, energy consumption of digital circuits becomes a major concern. The rising complexity of computing and processing requires faster devices such as field-programmable gate arrays (FPGAs) and other processing chips. Complicated processes demand higher power, which in turn causes fast chips to heat.

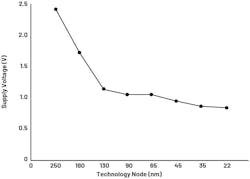

Figure 1 shows that the process technology trend in device dimensions is scaling down to the nanometer range. This necessitates a corresponding reduction in operating voltages, optimizing processing speed, and expanding the operational lifespan of devices.3

The trend of technology process optimization in turn requires highly accurate power supplies. If the actual performance of the power supplies isn’t considered, then it can lead to system performance risks. Since most regulators aren’t accurate enough, if the core voltage falls below the operating requirement, processing devices (FPGAs for instance) risk failure due to errors. And with continuous operation, if the core voltage drifts above the maximum operating requirement, this can damage the FPGA and create hold-time failures in the logic.

All of these risks can come with load condition, operating temperature, and aging.1 Though FPGAs are mostly mentioned as examples in this article, the same principle applies for other computing and processing devices.

Dealing with Tolerances

Tolerance needs careful attention when designing and monitoring power supplies for computing and processing chips, because it can be treated differently from each perspective. Such tolerances include:

Core Voltage Tolerance

The core voltage tolerance is the computing device core supply specifications. The table shows one example—the Altera Arria 10 FPGA core voltage specifications. The minimum and maximum values range amounts to ±3.3% tolerance with respect to the nominal value. Operating this device below the standard minimum or above the maximum will lead to performance issues. For optimum performance and low power operation, a tighter tolerance is required.

Power-Supply Tolerance

The power-supply tolerance is the output deviation or output regulation performance of the power supply. Obtaining a tight power-supply tolerance requires expert design. However, it can change over time due to several external factors, such as deterioration of components. In application, this power-supply tolerance should be within the core voltage tolerance.

>>Download the PDF of this article, and check out this TechXchange for similar articles and videos

Any operation of the power-supply output can cause problems to the processing and computing device, such as in FPGAs. A regulator with a declared tolerance may not operate exactly at the middle of the output-voltage regulation specification, but just within the regulation range. This can be due to the DC error brought by the standard value of resistors used in the feedback loop, which has inherent tolerance, robustness of reference voltage, and optimization of the feedback-loop compensation.

Consider an FPGA whose core voltage is supplied by a switching regulator as an example. This switching converter with a declared tolerance of ±2% may operate anywhere within the 4% window. It can be below the nominal value but still within the −2%, therefore putting an FPGA at risk of timing problems. Or it can be near the +2% ceiling, which can still meet the FPGA requirement but isn’t optimum and wastes a lot of power.1 Leaving this unmonitored, the device may eventually operate outside of the recommended voltage levels, which can lead to more serious problems and must be avoided.

Window Supervisor Tolerance

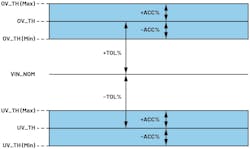

The window supervisor tolerance, or tolerance window, sets the undervoltage (UV) and overvoltage (OV) threshold in terms of percentage with respect to nominal value. For a window voltage supervisor with a nominal voltage value of 1 V and a tolerance window of ±3%, the UV threshold is set at 1 V × 0.97 and the OV threshold is set at 1 V × 1.03. These UV and OV thresholds, however, have their own tolerances known as threshold accuracy.

Using Window Voltage Supervisors

A window voltage supervisor ensures that devices operate within their specified voltage range by setting UV and OV thresholds. It issues a reset output signal if the supply voltage falls outside these set limits, helping to prevent system errors and protect electronic devices from damage.

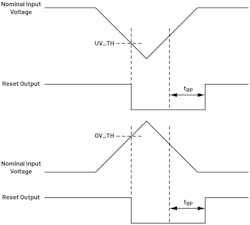

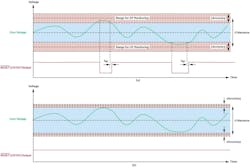

A timing diagram in Figure 2 shows how a reset output is provided when a monitored voltage falls below the UV threshold or exceeds the OV threshold. Several architecture options of window voltage supervisors are available to set the UV and OV threshold and chooe the operating tolerance that can be selected for optimum operation.2

However, choosing a window supervisor and using it optimally isn’t as simple as it seems. The appropriate tolerance window needs to be carefully selected from a range of available variants. In addition, reset thresholds for UV and OV come with their own accuracy specifications.

Threshold accuracy, typically expressed in percentage, is the degree of the conformance of the actual to the computed or target reset threshold, which is determined by a resistor divider and bandgap circuit in the integrated-circuit (IC) design.4 The more robust the reference voltage and the resistors, the higher the accuracy that can be achieved.

Figure 3 shows an illustration of the tolerance window and threshold accuracy in a window voltage supervisor. The actual thresholds of UV and OV, which are the UV_TH and OV_TH, respectively, can vary within the accuracy specification of the minimum and maximum value.

Power-supply performance budgeting is often done during system design. For an FPGA core voltage with ±3% tolerance or operating specification, ±1% can be allotted to power-supply DC regulation error, ±1% to the output ripple voltage, and another ±1% allowance for transient response.

Using a less accurate power supply with ±2% regulation error will leave less allowance for transients. This increases the risk of malfunctions to the device when directly supplied, as transients can go outside the core voltage specification window. Errors can be avoided by using window voltage supervisors to safely put the FPGA in reset mode when this happens.

Choosing the Right Tolerance Window

One of the common difficulties that crops up with a window voltage supervisor is setting and selecting the appropriate tolerance window. Users tend to choose a window voltage supervisor with the same tolerance as the core voltage requirement.

For example, a window voltage supervisor with a tolerance window of ±3% is used for a core voltage requirement that has a ±3% tolerance. Due to threshold accuracy, choosing the same tolerance with the operating requirement of the FPGA core voltage can trigger a reset output anywhere near the maximum overvoltage threshold OV_TH (max) and minimum undervoltage threshold UV_TH (min), leading to a potential malfunction.

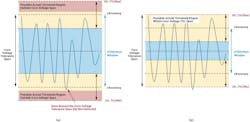

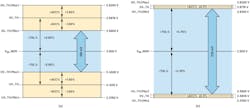

In Figure 4a, the monitored power supply could go beyond the core voltage tolerance and may not be detected by the supervisor on its possible actual operating threshold if threshold accuracy isn’t considered. This power supply going beyond the ±3% will be supplied to the core of a microprocessor; thus, a more appropriate choice of tolerance window needs to be chosen.

To avoid the risks of such a condition, the OV_TH (max) and the UV_TH (min) should be set within the ±3% tolerance requirement of the core voltage. Yet, a portion of usable power-supply window will be eaten by accuracy, which will give a reduced power-supply operating window (Fig. 4b).

The Impact of the Threshold Accuracy

Consider two window voltage supervisors with different threshold accuracies to monitor the same core voltage supply. The actual UV and OV thresholds of the one with higher accuracy deviate less than the one with lower accuracy with respect to the expected UV and OV threshold values.

In Figure 5a, note that a lower threshold accuracy will give a narrower power-supply window since the reset output signal will assert when the core supply voltage is anywhere within the UV and OV monitoring range. In applications with a low-accuracy power supply and poor regulation, this could lead to a more sensitive system that’s prone to oscillation. Meanwhile, high threshold accuracy gives an expanded and wider usable power-supply window, which improves system performance by operating stably, such as in Figure 5b.

Figure 6 illustrates an example of monitoring a 2.5-V core voltage with ±5% tolerance specification using two window voltage supervisors with different threshold accuracies. The tolerance window employed in this example may not be the actual available options, but they were chosen to account for the threshold accuracy.

The window voltage supervisor used has a threshold accuracy of ±1.5% and ±0.3% for Figures 6a and 6b, respectively. With a ±1.5% threshold accuracy, the optimum tolerance window (to avoid operating in a malfunction region shown in Figure 6a) is ±3.5%. This results in a power-supply operating window of 100 mV. With a ±0.3% threshold accuracy, the optimum tolerance window to maximize the power supply is ±4.7% without any malfunction risks.

These set values will give a power-supply operating window of 220 mV. This difference in accuracy improves the operating power supply window by more than double, maximizing power-supply performance.

The calculations were obtained using the Window Voltage Monitor Calculator, a tool that aids in understanding and visualizing the different parameters in a window voltage supervisor. This also enables users to check whether the device specifications fit the design requirements, such as the power-supply operating window. The tool is available for download from the following pages: MAX16138, MAX16191, MAX16193, MAX16132/MAX16133/MAX16134/MAX16135, MAX16137.

With continuous improvement in the architecture and performance of window voltage supervisors to address the demand of lower core voltages, threshold accuracies can now range from as high as ±1.5% to ±0.3%. And to enhance precision, these supervisors with a factory-trimmed nominal monitored voltage and tolerance window are available.2,5

The MAX16193, a ±0.3% accuracy dual-channel supervisory circuit, is a window voltage supervisor with the highest threshold accuracy across different temperatures (as of 2024), according to Analog Devices. A variety of factory-trimmed tolerance windows from ±2% to ±5% are available to accommodate different supply voltages and tolerances for industrial and automotive applications.

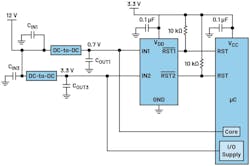

In a typical application circuit (Fig. 7), input channel 1 (IN1) monitors low core voltage rails from a 0.6- to 0.9-V threshold range with ±0.3% accuracy, while input channel 2 (IN2) monitors higher system rails from a 0.9- to 3.3-V threshold range with ±0.3% accuracy.

The MAX16193’s threshold accuracy specification is true for all temperatures within the operating range of −40 to +125°C. Figure 8 shows that the high threshold accuracy of the device for the two inputs IN1 and IN2 is true at different temperatures. While other voltage supervisors maintain optimum performance only on a certain range, this device guarantees high accuracy from the minimum up to the maximum operating temperature.

High Threshold Accuracy of Window Voltage Supervisors

To keep up with the demand in speed, power optimization, and advanced process technology, core voltages of devices are lowering and the tolerance is tightening. Window voltage supervisors help prevent serious problems in these devices. However, threshold accuracy plays a great part in operating within the device specification window. High threshold accuracy of window voltage supervisors helps maximize the power-supply performance by improving the operating power-supply window, thus preventing unwanted frequent resets and system oscillation.

References

1. Nathan Enger. “Care and Feeding of FPGA Power Supplies: A How and Why Guide to Success.” Analog Dialogue, Vol. 52, No. 11, November 2018.

2. Camille Bianca Gomez and Noel Tenorio. “Optimize Your System Design with the Right Window Voltage Supervisor.” Analog Dialogue, Vol. 58, No. 3, September 2024.

3. Mohammed Mahaboob Basha, Kota Venkata Ramanaiah, and Palakolanu Ramana Reddy. “Design of Near Threshold 10T-Full Subtractor Circuit for Energy Efficient Signal Processing Applications.” International Journal of Image, Graphics and Signal Processing, December 2017

4. Noel Tenorio. “How Voltage Supervisors Address Power Supply Noise and Glitches.” Analog Dialogue, Vol. 57, No. 4, November 2023.

5. “Voltage Monitors and Supervisors Product Highlights.” Analog Devices, Inc.

6. “Keep the Product Working-Microprocessor Supervisors Offer Big Insurance in Small Packages.” Analog Devices, Inc., November 2001.

7. Pinkesh Sachdev. “Design Note FPGA Power System Management.” Analog Devices, Inc., March 2020.

8. Caroline Hayes. “Designing Supply Voltage Supervision for Multirail Boards.” Electronic Specifier, October 2015.

>>Download the PDF of this article, and check out this TechXchange for similar articles and videos

About the Author

Noel Tenorio

Product Applications Manager, Analog Devices

Noel Tenorio is a product applications manager in the Industrial, Power, and Precision Group handling high-performance supervisory products at Analog Devices Philippines. He joined ADI in August 2016. Prior to ADI, he worked as a design engineer in a switch-mode power supply research and development company.

He holds a bachelor’s degree in electronics and communications engineering from Batangas State University, as well as a postgraduate degree in electrical engineering major in power electronics and a Master of Science degree in electronics engineering from Mapua University.

Camille Bianca Gomez

Product Applications Engineer, Analog Devices

Camilla Bianca Gomez is a product applications engineer at Multimarket Power—East. She joined Analog Devices in March 2022 and obtained her bachelor’s degree in electronics engineering from De La Salle University—Laguna Campus. She previously worked as a design engineer in an automotive manufacturing company for three and a half years and is now focusing on support and product development of high-performance supervisory products.