Sub-Scale Flow-Battery Prototyping System Speeds Energy Storage Research

What you’ll learn:

- Flow-style batteries are already demonstrating the potential to dramatically cut the cost of energy storage used to capture the excess output of grid-scale wind and solar plants for later use.

- A rapid prototyping and test system developed by Pacific Northwest National Labs (PNNL) uses a standardized “mini-flow cell” to reduce the amounts of time and materials required to evaluate new battery materials and processes.

- Developed using federal funding, the system is already producing results that will enable American battery manufacturers to compete for leadership in a rapidly growing global market.

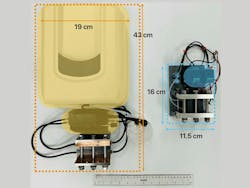

Flow-style battery architectures already show great potential for use in low-cost, long-lived utility-scale energy storage systems. Now, researchers at the Department of Energy’s Pacific Northwest National Laboratory (PNNL) are accelerating their commercialization with a rapid prototyping system that allows them to quickly evaluate promising new materials, processes, and technologies for flow-style batteries using compact, low-cost, “mini flow cells” (Fig. 1).

According to PNNL, their redesigned mini flow cell closely mimics the internal structure of a traditional flow cell, scaled down by a factor of 5. But, despite its smaller size, the mini flow cell exhibits comparable performance to its larger counterpart. As a result, the new battery test system requires an order of magnitude less starting material while delivering results equal to the standard lab-scale test systems.

Details of the new mini flow-cell design and experimental validation are described in an article published in the Journal of The Electrochemical Society.

Small Flow Battery Delivers Big Results

“This report is the first step, showing that scaling down our experimental system works,” said materials scientist and flow battery researcher Ruozhu Feng, a lead author of the study. “Our ultimate goal is to bring the power of AI and robotics into this process to automate and accelerate the testing of new flow-battery designs.”

By reducing the amount of material needed and speeding up the validation process, this technology could help advance renewable-energy solutions. Researchers also believe this miniaturized approach will facilitate experimentation with a broader range of experimental chemistries (Fig. 2).

“Currently, we have to prepare a lot of material when we identify a promising new battery formula, and this takes a lot of time,” said Feng. “With this mini flow-cell process, we can figure out whether a proposed new material works with only a tiny amount—milligrams—available.”

The mini flow-cell design is geared toward research laboratories that are focused on rapid screening and development of new battery materials. In their research study, the team showed that the new mini flow cell is suitable for rapid validation of material stability. Rigorous testing over a wide range of material chemistries and concentrations helped boost researchers’ confidence in the new scaled-down system.

Flow Batteries 101

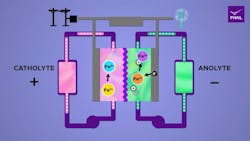

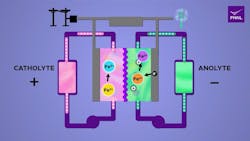

As their name suggests, flow batteries consist of two chambers, each filled with a different liquid. The batteries charge through an electrochemical reaction and store energy in chemical bonds (Fig. 3, top). When connected to an external circuit, they release that energy, which can power electrical devices.

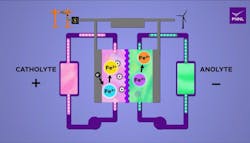

Flow batteries are a linchpin technology—they store energy from intermittent energy sources such as wind and hydroelectric power and then release that energy on demand for grid-scale applications (Fig. 3, bottom). Unlike traditional batteries, flow batteries use liquid electrolytes stored in external tanks, providing flexible scaling of energy capacity.

Accelerating Flow-Battery Evolution

Traditionally, the discovery of new materials for flow batteries has been a laborious trial-and-error process, often requiring gram-scale synthesis of organic compounds, extensive testing, and significant time investment. This new miniaturized cell design, about the size of a playing card, uses the equivalent of a few grains of sand, drastically reducing the time and resources required for each test while still delivering reliable results (Fig. 4).

In addition to Feng, Liyu, and Kim, the research team included PNNL scientists Chao Zeng, Carter C. Bracken, Yangang Liang, and principal investigator Wei Wang. This research was supported by the Energy Storage Research Alliance (ESRA), an Energy Innovation Hub funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences program, and by the Energy Storage Materials Initiative, a PNNL laboratory-directed strategic research investment.

The ESRA unites leading experts from national laboratories and universities to pave the way for energy storage and next-generation battery discovery that will shape the future of power.

A Team Effort Benefiting America’s Emerging Energy Industries

The key to their success, according to lead researcher and designer of the mini flow cell, Soowhan Kim, was that the team has over a decade of experience in flow-battery-cell design, along with engineering, skilled machining, and chemistry experience. For example, PNNL instrumentation and systems control expert, Andrey Liyu, used his mechanical engineering and microfluidics experience to complete the scale down without sacrificing accuracy.

“From small cells to big stacks, we can handle all scales of flow-battery design and experimentation,” said Kim, a lead researcher at PNNL’s Grid Storage Launchpad. “When we add the computational expertise and analytical chemistry experience, this is how we combined efforts to develop the mini flow cell. Our hope is to make this available to all researchers who are interested in using it.”

The research team has applied for U.S. patent protection for their new battery design. To learn more about collaboration or licensing opportunities related to the new technology, contact PNNL’s commercialization team.

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.