Electrically Controlled Solid-State Switch Manages Thermal Flow

What you’ll learn:

- Why is this type of thermal switch needed?

- How the ceramic material and structure was developed for superior performance.

- The results achieved with this material and arrangement.

Many engineers are naturally focused on getting heat away from their components, circuit boards, and systems. However, situations arise where it’s desirable and even necessary to dynamically manage the heat-flow path, change it, channel it, and maintain a desired setpoint temperature.

That’s where a thermal switch is needed. Applications for this function include thermal shutters, advanced displays, regulation of infrared heat transfer, and enhanced waste-heat recovery.

[Note that this thermal switch isn’t a thermally controlled electrical switch that flips its current-flow on-off state when a temperature threshold or trip point is reached (such as shown in “Graphene-Infused Foam Provides Dynamically Tunable Path for Thermal Management” and “Managing Distributed Power For Safety and Redundancy.”) Instead, it’s an electrically controlled switch that impedes or allows for the flow of thermal energy. In short: these thermal switches turn heat flow on and off. As often happens in technology, we have the same name for different or complementary functions.]

“Switching” to CeO2 Thin Films

A research team at the Research Institute for Electronic Science, Hokkaido University (Japan), devised a novel approach to implementing a thermal switch by using cerium oxide (CeO2) thin films as the active material. It provides a highly efficient and sustainable alternative to existing materials with performance that exceeds prior benchmarks.

For a variety of materials-science reasons, they focused on the electrochemical reduction/oxidation of CeO2 as an active material for thermal switches. For instance, CeO2 is an abundant material that’s widely used in practical applications such as polishing powders, catalysts, and sunscreens.

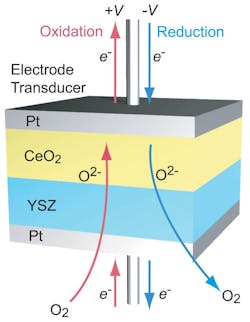

The structure of their solid-state electrochemical thermal switch has a 103-nm-thick CeO2 epitaxial film on a 0.5-mm-thick yttrium-stabilized zirconia (YSZ) substrate sandwiched between platinum (Pt) films. (If you’re not familiar with YSZ, it’s an inexpensive and widely used oxide-crystal substrate for the epitaxial growth of thin films.) The electrochemical reduction/oxidation treatments were performed at 280°C in the air.

When a negative/positive voltage is applied to the top Pt electrode, electrochemical reduction/oxidation of the CeO2 layer occurs. The top Pt electrode is also used as a transducer for thermal conductivity measurements (Fig. 1).

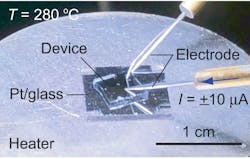

Their 5- × 5-mm device was placed on a heater at 280°C, and a negative/positive voltage driving a constant current of ±10 µA was injected at the top Pt electrode (Fig. 2). These treatments were performed by applying an electron density (Q) of 1 × 1021/cm3.

Switch Measurements and Results

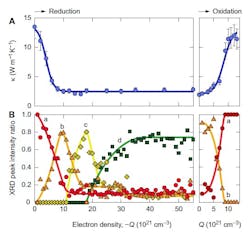

Measurement of thermal and related behaviors of these ceramic devices requires a range of advanced instrumentation, especially as they wanted to assess both macroscopic thermal performance as well as microscopic crystalline behavior. Their tests involved investigation of in-plane and out-of-plane x-ray diffraction (XRD) pattern of the device using high-angle annular dark-field (HAADF)-scanning transmission electron microscopy (STEM) observations, as well as thermal flow using time-domain thermoreflectance (TDTR).

Their device achieved an on/off thermal conductivity ratio of 5.8 and a thermal conductivity (κ)-switching width of 10.3 W per meter-Kelvin (W/m·K). The thermal conductivity in its minimal state (off-state) is 2.2 W/m·K, but in the oxidized state (on-state), it significantly rises to 12.5 W/m·K (Fig. 3).

Other tests investigated the switching speeds and relaxation times, as well as performance over many cycles. The researchers were especially proud of the cyclic results, as the performance metrics remained consistent after 100 cycles of reduction and oxidation, which they say demonstrated remarkable durability and reliability for extended usage in practical applications.

The work is detailed in their readable eight-page paper “High-performance solid-state electrochemical thermal switches with earth-abundant cerium oxide” published in Science Advances.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.