ViZn Energy Systems Inc. (ViZn) recently announced that it has bolstered its proprietary flow-battery technology to enhance the capabilities, reliability, and lifetime of all next-generation flow-battery systems for multi-megawatt energy storage applications. Designated “Vanguard II,” the battery stack further expands the operating range of ViZn’s systems by enhancing the fast switching and high-power cycling capabilities required for many applications, further maximizing ROI and providing industry-leading payback periods.

The Vanguard II battery stack has demonstrated 20% greater capacity and is immune to cycle-life degradation, providing more headroom to handle spikes in power requirements for demanding and unpredictable applications on both sides of the meter. All ViZn flow batteries incorporate the new Vanguard II stack-control technology, which eliminates life-limiting issues such as dendrite growth, simplifies cell balancing, and removes thermal and electrolyte breakdown issues associated with high-frequency power switching.

This unique multi-use capability is necessary for frequency regulation and other high-power applications while adding value to longer duration storage. All of ViZn’s systems are scalable, adding value for even the largest utility requirements. By interconnecting multiple units, both power and energy capabilities can be increased to offer utilities, as well as commercial and industrial customers the optimal fit for any size project.

Energy storage materially improves the stability and predictability of renewable energy. It allows higher penetration of renewables for distributed (commercial and industrial), micro-grid, and utility-scale applications where higher electricity prices, unstable grids, and lower regulatory hurdles provide a needed storage environment. Combining batteries with renewable energy can reduce diesel consumption by 75% and the cost of electricity by 40% to 50% over diesel generation alone.

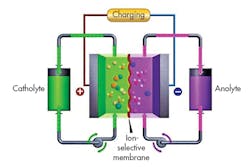

All of ViZn’s systems utilize the inherently safe, non-toxic, non-explosive zinc-iron electrolyte as shown in the simplified system in Fig. 1.The ViZn battery is a Redox type, which is a contraction of the terms “reduction” and “oxidation.” Redox flow batteries usually employ two electrolytes, acting as liquid energy carriers that are pumped simultaneously through the two half-cells of the reaction cell separated by a membrane.

On charging, the electrical energy supplied causes a chemical reduction reaction in one electrolyte and an oxidation reaction in the other. The ion-selective membrane between the half-cells prevents the electrolytes from mixing, but allows selected ions to pass through to complete the redox reaction. On discharge, the chemical energy contained in the electrolyte is released in the reverse reaction and electrical energy can be drawn from the electrodes. When in use, the electrolytes are continuously pumped in a circuit between reactor and storage tanks.

High-power flow batteries use multiple stacks of cells. The size and number of electrodes in the cell stacks is fixed and determines the system’s power rating. An advantage of this system is that it provides electrical storage capacity, limited by the capacity of the electrolyte storage reservoirs. Facilitating thermal management is use of the electrolytes as the thermal working fluids as they are pumped through the cells.

Flow batteries are typically sized for power by the physical dimensions of the electrodes. The next-generation flow batteries have greatly increased the ability to deliver power while maintaining the long-duration energy capacity.

ViZn’s zinc-iron Redox storage technology provides large-scale energy storage. A modular unit is a 20- or 40-ft. shipping container that can be combined and scaled to provide storage solutions for projects ranging from 100 kW to 100 MW. This technology provides safety, simplicity, and the use of abundant core non-toxic raw materials to achieve a 20-year expected life. Figure 2 shows a typical ViZn flow battery package and Fig. 3 shows the internal construction. Table 1 lists the characteristics of a five-stack, Z20-5 battery.

About the Author

Sam Davis

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.

You can also check out his Power Electronics blog.