Interconnect innovations span mmWave to fiber-optic communications

Makers of interconnect products are striving to meet customers’ demands for high performance in a variety of applications, from intrafacility fiber communications to 5G mmWave deployments. Commenting on the latter at the International Symposium in June in Philadelphia, Joe Rowan, Junkosha president and CEO for the United States and Europe, said, “The demand for mmWave frequencies is no longer the preserve of military and research applications. 5G and high-speed data applications are now driving innovation.” He placed his company at the forefront of the development of high-frequency interconnects, based on its expertise and pedigree in expanded-PTFE tape wrapping, which “…has enabled us to deliver a flexible phase-stable cable that endures.”

Connectors for aerospace applications

1.25-mm-pitch connector

mmWave interconnects

40-GHz skew-matched cable pairs

Hybrid active optical cable assembly

Board-to-board pin jumper

Right-angle cabled backplane connectors

New right-angle cabled STRADA Whisper backplane connectors are designed to help engineers improve the overall efficiency of their network equipment designs. They are primarily used to connect GPUs within a switch or server, opening up another avenue of options for system architects when designing equipment for high-density applications such as AI datacenters. At the same time, these new connectors continue to offer the same electrical and signal-integrity (SI) performance as the rest of the STRADA Whisper family. These products can support 56-Gb/s PAM4 with future expansion to 112-Gb/s PAM4. TE Connectivity

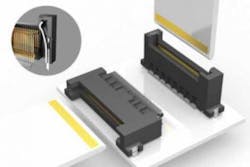

High-density edge card

Airframe cable assemblies

GORE-FLIGHT Microwave Assemblies 6 Series are lightweight cable solutions that deliver low insertion loss before and after installation, ensuring reliable performance for the life of the system. The robust construction of these assemblies reduces total costs by withstanding the challenges of installation, reducing costly production delays, field-service frequency, and the need for purchasing replacement assemblies. These lightweight assemblies improve fuel efficiency and increase payload.

Physical damage to the cable assembly during installation can result in impedance changes. The 6 Series airframe assemblies maintain a consistent impedance of 50 ±1 Ω.

W. L. Gore & Associates Inc.

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.