The evolution of AC power supplies

Download this article in .PDF format.

Recently, the applications in which AC power supplies are used have changed. Until now, because it was mainly used for testing home appliances and office equipment, a high-power capacity of several kW was required. However, with the progress of electrification of automobiles and aircraft power systems, and the increase in capacity of air conditioners and power conditioners, electric power of 20 kW or more is required. The trend to increase the capacity of AC power supplies is expected to continue through the near future.

To meet this trend, AC power supplies essential for compliance test or endurance test are required to support the demands for high capacity and multifunction. The performance of the large capacity AC power supplies required to test these applications should be the same performance as the small capacity AC power supplies.

Problems with previous high capacity AC power supplies

There are two different types of AC power supplies, but each has problems when used for evaluation tests such as EMC.

Linear type AC power supply

- Larger size

- Higher weight

- Lowest amplifier efficiency

- De-rating by low power factor

- Higher cost

PWM switched-type AC power supply

- Larger noise

- Slower response

Problems with linear type

Low noise and high response speed are required for testing power supplies. Linear-type AC power supplies are widely used in anechoic chamber and shielded rooms as test power supplies. Due to the large size of the equipment, a large footprint is required. Furthermore, because of its heavy weight, portability is poor, as it is difficult to relocate it once installed.

In the currently required applications, the power capacity is increasing year-by-year, and it is necessary to increase the power capacity by operating in parallel and the like. And in that case, size and weight become big restrictions.

Linear type is inefficient because of the dropper method, where the loss of the amplifier part is large in the form of heat. As a result, power consumption increases, and exhaust heat treatment is required. Therefore, in order to cool the installation site, it is necessary to manage air conditioning, which requires cooling costs.

In the case of an AC power supply for an anechoic chamber or a shield room, a large line filter is inserted at the output to remove noise. Linear-type power supplies are inefficient at low power factor, and equipment must be prepared according to the efficiency. Therefore, it was necessary to prepare a model of power that was larger than the power actually needed. This further increases installation site issues, exhaust heat treatment issues, and cost issues.

Problem with PWM switched type

On low-volume models, high-speed, low-noise, low-ripple products have been present. But on high-volume models, there are still problems such as high output noise (conductive noise) and slow response speed. Also, output impedance was high, and load fluctuation performance was poor. However, because PWM switched-type AC power supplies can clear many of the problems that linear AC power supplies have, these performance improvements have been sought.

Performance improvement of PWM switched type

Presently, even with a large capacity PWM switched-type AC power supply exceeding 10 kW, performance has been at the same level as the linear type power supply due to evolution of switching devices and the new topology:

- Low output distortion rate

- Low output impedance

- Fast response (<50us)

Evolution of power semiconductors

With the evolution of low-loss MOSFETs, SiC, GaN, and other power semiconductors, faster switching has become possible. Faster switching frequency contributes to the miniaturization of LC filters for making output waveforms sinusoidal. Along with this, cutoff frequency can be lowered, the amount of attenuation in the attenuation region can be increased, and noise at the switching frequency and its harmonic noise can be reduced. This achieves a low output distortion rate. Moreover, low output impedance is able to be realized by increasing amplifier gain.

Adopting a new topology

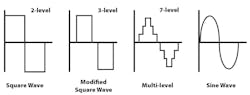

Multi-level type inverters represented by 3-level inverters have many advantages over conventional 2-level inverters. Since the output waveform of a 3-level inverter becomes closer to a sine wave, the LC filter for making output waveform sinusoidal can be miniaturized. In addition, since the voltage fluctuation range per switch operation is half that of a two-level inverter, switching loss generated in the switch element is approximately halved, and noise generated from the device is reduced.

By interleave control of the inverter, power supply is divided into two power lines and the current phase has a phase difference of 180 degrees, which cancels out the ripple and contributes to reduction of ripple noise. These improved performances allow us to use the PWM switched AC power supply for testing of high-capacity equipment.

Addition of regeneration function as further evolution

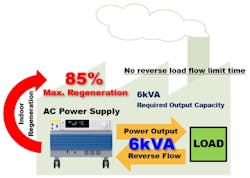

In the PWM switched-type AC power supply, current syncing couldn’t happen because power loss in the amplifier was not possible. Testing of power conditioners and car chargers, as well as in motor loads, the ability to sync current to the power supply is also required. Regenerative function is the solution.

In the linear type, because it was internally dissipated as heat, it was only possible to sync current at about 30% of the power rating. If this regeneration function is used, it is possible to regenerate up to the same power as the power rating of the device.

Converting AC power from conventional unidirectional PFC and DCDC to bidirectional inverter and DCDC is considered to be the mainstream of AC power in the future, since there are no major architectural changes or cost increases.

Takemi Iguchi is a technical advisory manager at Kikusui America, and has been with the company’s development division for more than 19 years.