This file type includes high resolution graphics and schematics when applicable.

Certifying a new power product to relevant safety standards is an essential part of any design and development process. But faced with a plethora of standards, engineers often need clarification regarding the nature of the specific tests addressing each standard, particularly high-potential (HiPot) testing.

What types of HiPot tests are there? Typically, there are two different types of test: design verification (DVT) and safety testing, which may take place first, followed by production and customer qualification testing. Confusion can occur sometimes when actual HiPot testing takes place.

For instance, misinterpretation of the relevant standard may result in testing a system to higher isolation safety test levels (3 kV ac and 4 kV ac) when the standard only requires production and customer qualification HiPot testing not exceeding 1.5 kV ac or its dc-rectified equivalent of 2121 V dc from input to output or input to ground.

HiPot Isolation Safety Testing

Isolation and insulation safety testing is among the most critical and most performed HiPot tests. Typically, two voltages are used to conduct HiPot isolation testing: 3 kV ac and 4 kV ac. For example, standard IEC60950-1 as it applies to ac-dc power supplies found in information technology (IT) and industrial equipment requires products to pass an input-to-output isolation test of 3 kV ac.

The IEC61010 standard applicable to test-and-measurement equipment also requires a 3-kV ac test. Standard IEC60601-1 covering medical equipment requires conduction testing at the higher voltage of 4 kV ac.

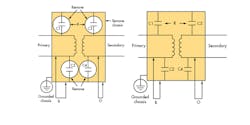

It’s important to know that 3-kV ac and 4-kV ac tests are stress tests for the main transformer only. These tests require the removal of the main transformer from the power supply for testing as a standalone part. Be aware that applying the 3/4-kV ac test voltages to the supply assembly will generate a failure, but it’s not a failure of the transformer as a protection barrier. It will be a failure of the basic insulation parts tied to ground (Fig. 1). For additional safety verification, running a 1.5-kV ac test checks the system’s two isolation barriers: input to output and input to ground.

A Typical Real-World Example

Obviously, end products must meet certain conditions specific to HiPot tests. If they don’t meet these necessary conditions or if an unusual scenario ensues, false failures may appear and possibly damage the power supply. Typical events include damage to input-to-ground and output-to-ground capacitors, primary-side field-effect transistor (FET) failures, and surge-protection device failures.

A typical real-world example involves a power supply complying with both IEC60950-1 and IEC60601-1. Under isolation testing from input to output at 4242 V dc (the rectified equivalent of 3 kV ac), a breakdown occurred from the input connection to the chassis. The breakdown happened because the supply’s isolation from the barrier strip to the chassis was specified to withstand a maximum of only 1.5 kV ac (2121 V dc).

The solution, outlined earlier, is to remove the transformer from the supply and test it independently at 3 kV ac. Alternatively, disconnecting the unit from its chassis and removing its Y capacitors will ensure a passing grade (Fig. 2).

These test issues are a particular problem in Class I equipment using a protective ground to ensure safe operation. Class II equipment employs double or reinforced insulation to ensure safe operation with no provision for protective ground. Class II supply users are able to test from the input to the output of the unit at 3 kV ac, or 4242 V dc, for IT devices and at 4 kV ac/5656 V dc for medical devices to verify insulation safety.

The Unusual Event

A not so typical scenario, one that demonstrates the importance of working with a knowledgeable power supply vendor, involves a product for testing and monitoring cell-phone networks. All testing went very well until it got to the nationally recognized testing laboratory (NRTL).

At the NRTL, the unit passed every test except the HiPot test, which was a bit of a surprise since the unit’s power supply carried medical safety approvals along with the necessary ITE approvals. This means the isolation is actually higher than what’s required for HiPot isolation tests.

The power-supply vendor verified that the test procedures and power-supply installation were correct. However, although testing was at well above 1.5 kV ac, it was not at 3-kV or 4-kV levels. Neither the vendor nor the OEM understood why the NRTL was testing above 1.5 kV ac, but the lab was quite were adamant that it was required.

Further investigation revealed that the test house was testing with such a high voltage because the OEM mistakenly labeled the product as having an input-voltage range from 80 to 264 V ac, the same input indicated on the datasheet for the power supply it was using. As a reaction, the NRTL based all HiPot measurements on 264 V ac rather than the standard 240-V ac value. Once realized, the OEM corrected the product label, reran the HiPot test at a standard 1.5-kV ac value, and the product passed.

Hindsight

In the mislabeling situation, the NRTL should have realized the input was a very non-standard rating and questioned the OEM about it. Unfortunately, the lab did not, costing the OEM a few extra days and a few headaches. But it shows that by working together, the OEM, vendor, and test lab can speed things along nicely to everyone’s satisfaction and safety.

EXTERNAL REFERENCES FOR READER INTEREST [Not included by author]

This file type includes high resolution graphics and schematics when applicable.

About the Author

Kent Smith

Senior Director of Marketing, Flash Components Division

Kent Smith is senior director of marketing for the Flash Components Division of LSI Corporation, where he is responsible for all outbound marketing and performance analysis. Prior to LSI, Smith was the senior director of Corporate Marketing at SandForce, which was acquired by LSI in 2012, his second company to be sold to LSI. He has over 25 years of marketing and management experience in the storage and high-tech industry, holding senior management positions at companies including SiliconStor, Polycom, Adaptec, Acer and Quantum. Smith holds an MBA from the University of Phoenix.