How Fast Can Your Battery Tester Change Voltage?

What you'll learn:

- Measuring rise time for a power source.

- Voltage vs. time signals measurements via a scope.

- A practical setup for battery testing.

I was recently asked a question about a dc power supply, aka a voltage source, that would be used to charge a battery module during test: “What is the rise time of this voltage source when applying 0- to 350-V step under a load of 400 mA?” While this question was about charging a battery module, the question is really a general question about how to measure the performance of a voltage source.

The rise-time specification of the questionable power source was specifically stated as a transition from 0 to 600 V at full load current of 2.6 A, and it would take 250 ms. Though this specification was clear, the conditions under which this specification is stated were quite different from the requested conditions. The 0- to 350-V transition was about 60% of the 0- to 600-V specification and the current of 400 mA is about 15% of the 2.6-A specification. Under these less stringent conditions, the rise time is likely less than 250 ms, but how much less?

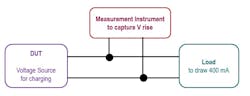

The question seemed simple enough to answer by measurement. Just set up the voltage source, apply 400 mA, then program the source to step from 0 to 350 V and measure the rise time (Fig. 1). However, as I began thinking this task through, I realized it was challenging.

As you may find yourself in a similar situation one day, I thought you might find the steps I followed to be instructional. In fact, done improperly, the resultant measurement could be wrong, or worse, destructive to the battery module or the test equipment.

Setting Up a Test to Measure Battery Tester Voltage Change Speed

To measure the rise time, we’ll need to create a test configuration and gather the right equipment. The device under test (DUT) is the power supply being measured. To create the 400-mA loading on the DUT, we need some kind of load, like a resistor or an electronic load. Measuring the rise time requires some kind of measurement instrument that can capture the DUT output-voltage waveform.

For the load on the power supply, we need a solution that can provide 400 mA. The simplest choice might be a resistor. Using Ohm’s Law (V = A * Ω, or V = I * R), you can calculate the size of the resistor to be R = V/I, or 350 V/400 mA, which is 875 Ω. This resistor will need to be a power resistor.

To calculate power in a resistor, use the formula Watts = (the square of the current) * Resistance, or W = I^2 * R. At 400 mA and 875 Ω, this calculates to 140 W. Finding an 875-Ω power resistor capable of handling 140 W will certainly be a challenge.

But is a resistor the right choice? This 875-Ω resistor will only draw 400 mA when the power supply is at 350 V. At 0 V, the resistor will draw 0 mA and at 175 V, or halfway to 350 V, the resistor will only draw 200 mA. Thus, the conditions generated by the resistor don’t meet the criteria of 400 mA during the rise from 0 to 350 V. Instead, what’s needed is a constant current generated by an electronic load, or “eload.”

While the current of 400 mA is small, the 350 V is high. Most eloads aren’t rated to operate at these high voltages, so finding the right eload may be difficult. Furthermore, eloads have a minimum operating voltage, typically around 2 V. If the minimum operating voltage isn’t applied to the eload, the eload will not be able to regulate properly and the 400-mA constant current will not be achieved.

>>Download the PDF of this article

This unregulated condition will be resolved as soon as the power supply’s voltage rises above the eload’s minimum operating voltage, so there’s not a real problem for making this rise-time measurement. However, when viewing the rise-time measurement, we may see some distortion at low voltage while the eload is unregulated.

Performing Voltage vs. Time Signal Measurements with an Oscilloscope

For the measurement, since we’re trying to measure a voltage vs. time signal, we’ll need some kind of oscilloscope or digitizer. One might be tempted to use a standard digital multimeter (DMM), but it can’t show the time-varying voltage signal.

For this voltage measurement, the challenge is that the voltage is quite high. An oscilloscope is a natural choice, as the display can easily show the waveform to give confidence that we’re measuring the right signal. Most oscilloscopes have markers or some built-in analysis that can allow us to read out the rise time right off the display.

However, for an oscilloscope to measure 350 V, a high-voltage probe is needed. You may also want to capture the current during this rise-time measurement to ensure the test conditions are achieved. This will require capturing current vs. time, which means the oscilloscope will need a current probe as well.

Lastly, an oscilloscope is ground-referenced. Since the DUT is a power supply that can float with respect to ground, connecting this power supply to the oscilloscope will ground the power supply, but that will not be an issue for this floating DUT. However, it’s always important to be aware of grounding paths when using ground-referenced instruments, like oscilloscopes, around power supplies and batteries. If you’re not mindful that the oscilloscope will ground the setup, the unintended ground can damage the oscilloscope and possibly short the power supply or battery, with potentially catastrophic results.

Using a digitizer is complex and has the same considerations with regard to high-voltage measurement, current measurement, and grounding. Another choice would be a power analyzer, sometimes known as an AC power analyzer. Even though this rise-time measurement is a DC measurement, AC power analyzers can capture DC waveforms, measure high voltages (typically 1,000 V AC and 1,000 V DC), measure current without a current probe, and aren’t ground-referenced.

Therefore, the AC power analyzer, such as Keysight’s Integravison, becomes a great option for this measurement. However, power analyzers are far less common in laboratories and may not be familiar to some engineers, scientists, or technicians who may be making these measurements.

Practical Setup for Accurate Battery Testing

Given that finding the right eload was going to be the biggest challenge, we set out to locate the right instrument for the job. We selected a two-quadrant power supply that’s rated at 500 V and ± 20 A. While this two-quadrant supply is overkill in power, it can easily handle the test voltage and accurately pull the required constant current.

Furthermore, this specific two-quadrant power supply, Keysight's RP7951A, has a built-in digitizer for voltage and current. Thus, we can easily capture the rise time and measure it without the need for an oscilloscope, high-voltage probe, and current probe. Figure 2 shows the simple test setup.

Another benefit of using the RP7951A is that it can be controlled by a companion software application, which controls all of the RP7951A’s features and provides a clear UI for visualizing the captured digitized voltage and current signals.

Results: Measuring Voltage Rise Time in Battery Testers

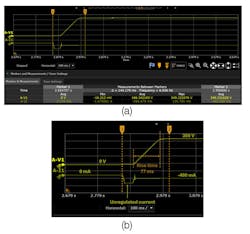

Figure 3 is a screen grab of the companion software. Figure 3a shows the full user interface and Figure 3b zooms in on the region of interest. Trace A-V1 is the voltage out of the DUT and trace A-I1 is the current out of the DUT. The rise time is easily read on trace A-V1 on the screen to be 77 ms.

Also note the behavior of the current. Marker 1 is located where the 400-mA load was applied. At marker 1, the voltage is zero because the DUT hasn’t started its 0- to 350-V transition. Because the voltage is zero, when the current is applied, the RP7951A, acting like an eload, is unable to regulate the current. For about 50 ms, the unregulated current isn’t achieving the desired 400 mA.

At the end of the 50 ms, when the DUT begins slewing from up 0 to 350 V, you can see the current overshoots slightly and then goes into regulation at 400 mA. This is evidence of the low-voltage behavior described earlier in this article. While the setting was 400 mA, the actual measured current is −402.298 mA, shown in the measurement panel of marker 2 on the bottom right of the image. By convention, load current is shown as negative.

>>Download the PDF of this article

About the Author

Bob Zollo

Solution Architect for Battery Testing, Electronic Industrial Solutions Group

Bob Zollo is solution architect for battery testing for energy and automotive solutions in the Electronic Industrial Solutions Group of Keysight Technologies. Bob has been with Keysight since 1984 and holds a degree in electrical engineering from Stevens Institute of Technology, Hoboken, N.J. He can be contacted at [email protected].