Members can download this article in PDF format.

For market growth to occur at desired levels, suppliers must meet consumer demand for compact electronic devices that integrate multiple functions. To satisfy this requirement, engineers in turn must balance function, power consumption, and space constraints while managing rising system costs.

This juggling act encompasses performance, size, and power efficiency—the trouble is that improving each element has become increasingly difficult. As systems grow more complex, traditional discrete logic designs often require multiple ICs to handle various functions, such as timing, resets, and voltage monitoring. Due to the number of individual components, these designs consume significant board space, increased power consumption, and higher manufacturing costs.

Greater design complexity fuels the need for more integrated logic solutions to meet application requirements. Unlike discrete logic, programmable logic devices (PLDs) enable designers to reduce their component count and shrink PCB footprints (by as much as 94% in Texas Instruments’ case). The results are lowered costs, shrunken bill-of-materials (BOM) lists, and even lower power consumption as a result of more cohesive system operation.

Sponsored Resources:

- Simplify and Customize Your Logic Design with PLDs

- TI Programmable Logic Devices (PLDs) Portfolio

- Explore New Possibilities with TI Programmable Logic Devices

PLDs to the Rescue

A new range of PLDs from TI allows engineers to easily design and integrate complex logic functions into their circuits with minimal coding. They also significantly reduce board space and speed up development time.

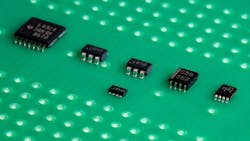

As mentioned, traditional discrete logic implementations can be cumbersome, adding to design complexity and limiting flexibility when changes are required. TI’s new programmable logic offerings, however, can combine up to 40 combinational and sequential logic elements along with analog functions into a single device (Fig. 1).

The devices reduce the number of discrete components needed and trim board space up to 94% compared to discrete logic designs. By incorporating sequential and combinational logic in compact packages, the new PLDs also lower system costs.

Integrated logic solutions help engineers meet application requirements. PLDs can reduce solution size, lower design and manufacturing costs, assist with managing the supply chain, and speed time-to-market.

Design Tool Helps Engineers Easily Build Logic Circuits

When paired with TI's no-code design tool—known as InterConnect Studio—PLDs reduce development time by enabling drag-and-drop circuit creation and simulation without programming expertise.

The free InterConnect Studio design tool enables engineers to easily build logic circuits, fine-tune logic elements, check for errors, and even view a power-consumption estimate without any coding experience. You can manipulate the built-in simulator for different probe points to view all sections of your design and confirm that it meets your requirements.

With quiescent current less than 1 µA and featuring 50% less active power than similar devices on the market, TI’s new PLDs offer low power consumption to help extend battery life in products such as electric vehicles, power tools, battery packs, and gaming controllers.

TI’s PLDs support general-purpose input/output, lookup tables, digital flip-flops, pipe delays, filters, and resistor-capacitor oscillators. Its TPLD1201 and TPLD1202 devices also integrate analog functions such as analog comparators, with internal selectable voltage-reference options and hysteresis. The TPLD1202 offers additional elements such as a Serial Peripheral Interface, I2C, watchdog timer, and state machine (Fig. 2).

60 Years of Experience

TI PLDs are suitable for use across multiple markets, including automotive, industrial, and consumer electronic applications. The company’s PLD portfolio includes the industry's smallest leaded package, measuring 2.1 × 1.6 mm with a 0.5-mm pitch. This leaded package is 92% smaller than competing devices, supporting manufacturers’ need for solderability—at a fraction of the size.

The automotive-grade PLDs are as much as 63% smaller than their closest competitors. The portfolio also offers quad flat no-lead (QFN) packaging options that enable automated optical inspection, helping to ensure safety and long-term system reliability.

The portfolio, which builds on TI’s 60 years of experience in logic design, also offers low power consumption, AEC Q-100 qualification, and a temperature range of −40 to 125°C.

From Concept to Prototype in Minutes

Numerous programmable logic solutions are accessible to designers today. TI’s PLDs are available in smaller packaging options, resulting in smaller printed circuit boards and lower production costs, ultra-low power consumption, a smaller number of logic elements, analog functionality, and easier programming when compared to other programmable products.

Sponsored Resources:

- Simplify and Customize Your Logic Design with PLDs

- TI Programmable Logic Devices (PLDs) Portfolio

- Explore New Possibilities with TI Programmable Logic Devices