I was recently at the 2017 Consumer Electronics Show (CES) looking for interesting and unusual technology. These gems are often found in the backrooms and hotel rooms where most attendees cannot enter. Such was the case with TDK, which had a number of interesting technologies. This is one of them.

TDK is using its advanced piezo-ceramic materials and processes expertise to bring a family of piezo electric disks (Fig. 1) to the haptic feedback market. They provide vertical displacement that can be controlled to provide a range of effects.

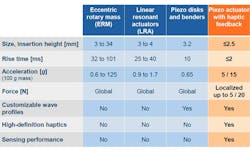

Most haptic feedback systems are implemented using an eccentric rotating mass (ERM), a linear resonant actuator (LRA), or simple piezo disks or bars (Fig. 2). They tend to generate global effects for a device, as well as deliver a limited amount of force. While they work for many applications, they tend to fall short for others (such as buttons). The more limited travel/displacement and force often make operation less useful when used with gloved hands.

TDK’s design uses a multilayer, piezo-electric system (Fig. 3). It is currently available in two form factors: the 5N (12.7 mm2) and 20N (26 mm2) types. These can deliver 5 g and 15 g of force, respectively. The piezo effect has a constant volume change; metal cymbals are placed on the top and bottom of the stack to amplify this movement.

TDK’s thin piezo actuator are less than 2.5-mm high and tend to provide significantly better performance than the competition (Fig. 4). The solution is very thin while delivering superior acceleration with faster rise times under 2 ms. This allows a wider range of effects to be delivered. The force is also localized, which is more desirable in many applications (e.g., large buttons). Multiple actuators can be combined to provide other effects. Best of all, the system can provide sense feedback.

The parts will be showing up in applications ranging from whitegoods to industrial equipment. They are ideal for automotive applications, where users may be wearing clothing that could affect other solutions.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.