Gold-Plated Plastic Connectors Cut Costs

What you’ll learn:

- What’s new about Corning’s Polylink connectors.

- Where plastic connectors make sense.

Connectors are typically designed to be robust and utilized multiple times with ratings that go into hundreds of cycles. That’s why all-metal connectors are the norm. Not every application requires this level of ruggedness, though, which is where Corning Gilbert plastic Polylink connectors come into play (Fig. 1). I talked with Mike Voskresensky, Senior Applications Engineer at Corning, about the new connector family (watch the video above).

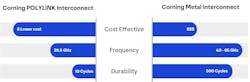

The Polylink plugs and sockets are gold-plated, plastic, blind-mate interconnects that trade off durability and maximum bandwidth for lower cost (Fig. 2) compared to typical beryllium copper parts. They also weigh 30% less than conventional metal components. Polylink connectors top out at 26.5 GHz, but that’s often more than sufficient for many applications. Of course, those that require higher frequencies will need to stick with conventional connectors.

The connectors can handle rugged applications, making them suitable for automotive, aerospace, and defense applications. They feature 0.005 axial compression and maintain intermateability with standard Corning GPPO connectors. The operating temperature range is −65 to +125°C.

While 10 mating cycles may not appear to be much, it works for many applications where connections are relatively permanent or for prototyping. The lightweight connectors could be useful in applications such as drones.

Links

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.