Copper: Conductivity Benefits and Environmental Impact

What you'll learn:

- Copper's role in clean energy initiatives.

- Issues with copper mining.

- Possible alternative materials to copper.

- Copper and the circular economy.

Most circuit designers probably aren’t thinking about, much less worrying about, the metal copper. But as the electrification of the world continues, copper conductors used in applications from microchips, other components and circuit boards, to household, industrial, and automotive wiring, and critical workhorses like batteries and electric motors, points to the need to spotlight its starring role.

This article is mainly informative, but you can take some actions in your professional and personal life to help manage this important material.

Critical Minerals and Copper’s Role in Clean Energy

We begin with a pair of quotes from the International Energy Agency (IEA; bold on the word copper added here by the present author).

“An energy system powered by clean energy technologies differs profoundly from one fueled by traditional hydrocarbon resources. Critical minerals such as copper, lithium, nickel, cobalt and rare earth elements are essential components in many of today’s rapidly growing clean energy technologies—from wind turbines and electricity networks to electric vehicles.

“Lithium, nickel, cobalt, manganese, and graphite are crucial to battery performance. Rare earth elements are essential for permanent magnets used in wind turbines and EV motors. Electricity networks need a huge amount of aluminum and copper, the latter of which is the cornerstone of all electricity-related technologies.”

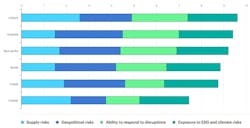

The growing need for energy-critical materials as well as other global factors means that ongoing supply capacity may face risk. Four such risks have been estimated by the IEA (Fig. 1). In order from left to right, they are:

- Supply risks

- Geopolitical risks

- Ability to respond to disruptions

- Exposure to ESG and climate risks

ESG refers to Environmental, Social and Governance, which may affect reporting and compliance with regulatory requirements, including the financial well-being of a company. So, it’s good for electrical and electronic professionals to have some basic familiarity with this growing trend.

In the chart, you can see decreasing risk from lithium to graphite, the rare earths, nickel and cobalt, down to copper at the bottom.

Where is Copper Found?

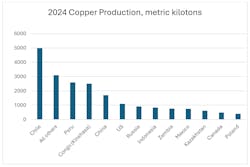

As geochemistry would have it, copper is widely distributed across the globe. The largest production of copper is in Chile, followed by a dozen other countries including Peru, Congo, China, U.S., and Russia, on down to several other main producers shown in Figure 2.

To emphasize the worldwide distribution aspect, the number two producer is all of the other countries not specifically named. This may be seen as some good news, helping to reduce the risk factors listed in Figure 1.

Environmental Impact of Copper Mining: The Issue of Mine Tailings

Mining metals isn’t a clean process. Most of these operations will leave large amounts of excess material known as tailings, of which there are as many as 18,000 such dumps worldwide.

These may be in the form of a slurry or sludge that’s retained in ponds typically contained by earthen dams. Failure of these dams leads to uncontrolled, massive spills containing toxic metals and other substances. When this happens, millions of gallons of the tailings are released, contaminating downstream water.

Even when such disasters don’t occur, the tailings may dry out and release the toxins as fine particles into the air. Let’s be clear by noting that dust containing metals like zinc, lead, antimony, and arsenic are unfit to breathe, especially for small children.

Regulating such tailings is difficult at best and further compounded by the fact that many sites are so old that ownership isn’t clearly defined. This is an example of an outdated last-century industrial practice that didn’t properly consider or effectively deal with the long-term effects of operations and their impact on the environment. They were pushed aside as someone else’s problem or simply ignored.

Possible solutions to avoiding the problems of tailings as discussed below include increased recycling of already mined and refined copper and developing nanotechnologies like those based on carbon rather than metals.

Potential Copper Alternatives in Electrical Applications

It has been suggested to consider more abundant metals, including iron, aluminum, and magnesium, as possible alternatives for copper. It doesn’tseem likely, however, that this will become widespread or even necessary in the near future.

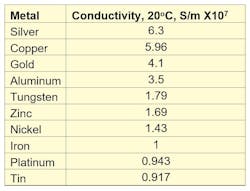

While the engineering, supply, and cost considerations are complex, it’s easy to see why copper is so often the conductor of choice. Figure 3 is a basic list of metal conductivity. The precious metal, silver on top, like gold below copper, are pricey and often used only sparingly in applications like contacts.

Though the other metals are generally considered as conductors, their other properties and greater resistance losses aren’t desirable in most cases as a main choice. Still, they may fill niche functions within a component or system. Zinc is commonly alloyed with copper to make brass used in connectors, and/or with tin to make bronze, while nickel and tin are commonly found in component terminations in addition to the precious metals.

Not listed in this table of metals is another developing alternative in the realm of nanotechnology where carbon nanotubes and graphene are seeing development and growth. The conductivity of these materials is not only competitive with, but may even exceed, the conductivity of copper. Cost and availability concerns remain high at the present time, but the reader is encouraged to be aware of this upcoming technology.

One of the possible environmental benefits of carbon-based technology could be the abundant availability of starting material since the element carbon is within us and all around us. And, while the materials must be manufactured, unlike metals they require no mining with its resultant tailings.

Copper’s Role in the Circular Economy

Plainly stated, combustion engines consume fuel and burn it to carbon dioxide, water, and various undesirable side products. Metals like copper to power the world with electrical energy aren’t consumed but used for years. Then they may be recovered, recycled, and reused over and over.

This fundamental difference is one of the drivers of broad initiatives like that of the European Union’s “Circular Economy.” This builds on the existing WEEE Directive (Waste Electrical and Electronic Equipment) that requires diversion of such equipment from landfills and incineration to a closed material loop.

From a more technical perspective, guidance like the series of European standards EN 50625 Collection, Logistics & Treatment requirements for WEEE, and its technical specification 50625-5, specifically address copper and precious metals in electronics.

Conformance requires that 100% of copper, gold, silver, and palladium be collected as inputs to recovery, with a minimum 90% resulting yield for all four metals. These metals can then be returned to the stream of commerce and merged with newly produced metal to continue new product production.

Other parts of the 50625 series of standards are specific pretreatment of lamps, CRTs and flat-panel displays, temperature exchange equipment containing refrigerants, and photovoltaic panels, which should be of particular interest if working on those products. (Links to the full standards cannot be provided here since the documents must be purchased from the owning organization or authorized publisher.)

Closed-loop product lifecycle thinking isn’t new to the electronics industry since regional collecting, recycling, and reuse of electronic consumer products has been practiced for several decades. The current US EPA guidance terms this “donation” rather than mandatory collection.

Recycling organizations like e-stewards provide certification for recycling operators who conform to best practices and has a searchable index of global recycling companies by region. Your local solid waste authority may also offer such services, for example, drop-off locations or scheduled curbside pickup of WEEE.

From a practical perspective, your copper and similar metals would most likely fit under the scrap category of Recycled Materials Association (ISRI) Scrap Specifications Circular code EM3, Circuit boards and Shredded Circuit boards From the Processing of End-of-Life Electronics. More along these lines may be found in the article “Making Electronic Products More Recyclable.”

Key Takeaways on the State of Copper

That copper is a most capable electrical conductor isn’t news, but hopefully the insights on its origins, side effects, and environmental lifecycle impacts has been interesting and useful to you. We conclude with these takeaways:

- Copper is an important contributor to the overall circular life of electronics.

- How our professional work impacts the environment deserves to be more widely understood.

- Alternative conductor materials based on carbon nanotechnology are being developed.

- You can use this information in your daily life when you recycle rather than dispose of your obsolete or nonfunctional electrical and electronic equipment.

Penny for your thoughts.

About the Author

Roger L. Franz

Environmental Sustainability Advocate and Contributing Author

Roger Franz has served as Principal, Engineering IT at TE Connectivity, Research Engineer at UL Environment, and Group Leader and Design for Environment Manager at Motorola. In addition to product environmental compliance and standards, his passions include new product development, quality, and technology research. His papers have appeared in several industry journals. He has had over a dozen article published in Electronic Design. He holds a BA and MS in chemistry from Grinnell College and Northwestern University, respectively.