Add Up-Front PCB Design Intelligence to Avoid Last-Minute Mistakes

This article is part of the TechXchange: PCB Tools and Technology.

Download this article in .PDF format

Printed-circuit-board (PCB) designers today are dealing with an array of new challenges, including greater electronic and mechanical design complexity, tighter constraints and rules, and the need to stay on top of a fast-changing supply chain. These and other emerging issues can cause extra design spins that drive up engineering costs and delay product introductions, ultimately costing you money.

Leading-edge PCB design tools are helping to address these concerns by providing up-front design intelligence that addresses these and other areas of the design process. Rules and constraints can be established earlier in the design process, reducing the need for potentially expensive changes late in the design process.

Electrical design is becoming more integrated with mechanical design so that, for example, changes can be pushed from the mechanical computer-aided design (MCAD) environment to the electrical computer-aided design (ECAD) environment and vice versa. Finally, embedded component-management systems are keeping designers up to date on availability, delivery, and pricing.

PCB Design Tools Must Expand Beyond Automatic Routing

Component placement and routing were the original capabilities offered by PCB design tools and these capabilities are still vital to today’s designers. Today’s leading-edge design tools help maximize routing efficiency and flexibility with interactive routing that lays route sections along the cursor path, enables pushing or walking around obstacles, and automatically follows existing connections. Cursor-guided routing makes complex manual routing around obstacles fast, easy and intuitive. You create the path of the route with your mouse and the interactive router attempts to place the tracks according to that path.

Figure 1 shows how complex routes can be created quickly with the routing path guided by cursor movement. The left image shows a normal, minimal length route, the center image indicates the cursor path, with stars indicating where clicks were made to commit sections of the route. The right image is the resultant routing. Although an extreme example, it shows how few routing commits are required to place many tracks.

Cross-select component placement saves time by making it possible to select specific components on the schematic in a specific order and then place those components on your board layout in the order they were selected. This helps to keep your designs closely aligned and organized, and easy to edit in the future.

Establish Rules and Constraints Earlier in Design Process

As functionality, power dissipation, and signal speed increase, while enclosures shrink, design rules are becoming tighter and more difficult to manage. New PCB design software is helping to address this challenge by enabling designers to set up rules and constraints earlier in the design process. It ensures the logical and physical integrity of the design and minimizes the need for changes later on.

Checks against any or all enabled design rules can be run in real time as you work, as a batch check with results listed in the messages panel, or within a generated report. This feature should be used on every routed board to confirm that minimum clearance rules have been maintained and that there are no other design violations.

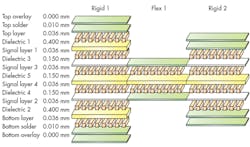

Defining, managing, and documenting the layer stack has also become a much more critical issue with the increase in the number of layers in typical PCBs. This challenge is increased by the advent of flexible PCBs comprised of a series of rigid and flexible layers that can be folded to fit into unusually shaped enclosures (Fig. 2). These copper layers are defined in the design environment along with layers of insulation material that separates them.

New layer-stack management tools are being developed to create multiple layer stacks within a single PCB design, simplifying the task of defining a rigid-flex PCB. The first step is defining the overall shape of the PCB. Next, the designer defines a master set of layers, including all layers needed in the rigid-flex design. The designer has the ability to define multiple layer stacks, where each stack includes only the layers needed for each rigid and flexible zone of the PCB. Different rigid and flexible zones are established where each sub-stack is applied. Finally, the designer generates the detailed output fabrication and documentation files needed to fabricate the rigid-flex PCB.

Mechanical Integration Needs Extend Beyond Interchange File Formats

Packaging and electronic assemblies are becoming more tightly integrated than ever before due to increasing design complexity and reductions in enclosure size. The manual import and export of neutral file formats is limited by the time-consuming nature of this process as well as the potential for data loss that can occur when 3D MCAD data is moved into a 2D PCB design environment.

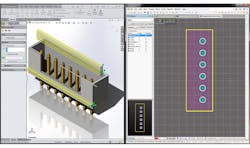

Cutting-edge PCB design systems address this challenge by automating the process of pushing changes to component placement, board shape, mounting holes, etc., between the MCAD and ECAD environments (Fig. 3). A detailed comment and revision history shows exactly what changes were made to the design, and both MCAD and ECAD designers have the ability to accept or reject changes. Board assemblies can be exported to the mechanical designer’s environment with included copper geometries, making it possible to perform detailed thermal, vibration and other simulations.

Overcoming Part-Selection Difficulties

When you pass by the desk of an electronics engineer, you are likely to find a stack of catalogs of components from favorite suppliers. The catalogs are usually well-worn because the engineer consults them on a regular basis to search for needed circuit components and answer questions such as: “What parts are available?” “What functionality do they offer?” “What are their specs?” “How much do they cost?” and “How quickly can they be delivered?”

The problem with this approach is that lots of time is spent paging through catalogs, and frequently, the data in the catalogs turns out to be outdated. The worst-case scenario is that the problem is not discovered until late in the design cycle and ends up affecting the product delivery schedule.

The most advanced PCB design systems can help overcome this problem through direct connections to supplier web services, making it possible to search across the supplier’s online product catalog to ensure that the information generated in the search is current. This live data—parametric information, datasheet links, pricing and stock information, etc.—can be instantly incorporated into the design, saving the time that would otherwise be required for manual data entry. A live link can be incorporated in the design so that the information will automatically update when a change is made to the supplier’s online catalog.

Designers can also choose to be notified when such changes are made so they can take action to avoid disruptions to the supply chain. Moreover, they can specify alternative part choices to maximize their flexibility to respond to a dynamic supply environment. The primary and alternative part choices will automatically be swapped if a primary component becomes unavailable or incompatible through a specifications change.

Conclusion

The greater complexity of today’s designs combined with smaller enclosures and more turmoil in the supply chain creates the potential for problems throughout the design process. In particular, issues arising in the late stages that may result in cost overruns and delivery delays. Traditional PCB design tools, developed in a time when the PCB design process was simpler, leave a lot to be desired in addressing these concerns.

Advanced PCB design tools provide a substantial improvement by providing up-front intelligence in areas such as routing and component placement, definition of design rules and constraints, ECAD/MCAD co-design, and supply-chain management. These help PCB designers overcome today’s design challenges and avoid late-stage problems.

Looking for parts? Go to SourceESB.