Streamlined Multi-Touch HMI Leverages Capacitive-Touch Technology

Capacitive-touch technologies (with either surface capacitive or projected capacitive sensing mechanisms) now constitute more the half of the global touchscreen market, according to information compiled by industry analyst firm IDTechEx. Already used in myriad portable consumer products such as smartphones and tablet PCs, capacitive touch is now appearing in domestic appliances, industrial control equipment, and home-automation systems.

Although the lower cost presented by resistive touchscreens makes them attractive to many electronics markets, increased display brightness and quicker response times delivered by human machine interfaces (HMIs) based on capacitive touchscreens continue to gain traction among the engineering community. However, multi-touch functionality will likely become the primary driver for capacitive-touch-based HMIs in the coming years.

Multi-touch operation makes it possible to determine all manner of complex gestures, which will conceivably lead to much less frustrating, more intuitive user interaction. In addition, multi-touch allows several people to utilize the same HMI simultaneously to create shared user experiences.

This file type includes high resolution graphics and schematics when applicable.

Traditional Vs. Streamlined HMI Designs

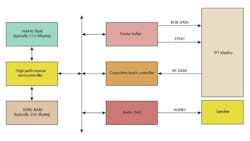

Considering capacitive touch’s expected push into a broader spectrum of HMI designs, engineering teams must ensure they can implement this technology in the most effective way possible. A typical circuit for a multi-touch HMI implementation requires the presence of a large amount of silicon, including a high-performance microcontroller unit (usually 32 bits), a sizable flash memory for storing image data, and a large-capacity frame buffer that passes the data to the display (Fig. 1). Such a circuit also requires wide parallel buses to take care of communication between various onboard ICs. Board-space requirements and bill-of-materials costs, however, can potentially be restrictive for this type of system.

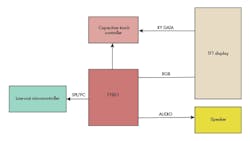

A simpler, more streamlined multi-touch HMI circuit design (Fig. 2) can display bitmap images that are easily resizable via a two-finger stretch/shrink gesture. They can also change the orientation of these images using a multi-finger rotate gesture. On top of that, adequate opportunities exist for other gestures to be put in place, including two-finger taps, page flicks, cut-and-paste, swipes, two-finger long presses, etc.

What sets this system apart from other HMIs is that all audio and visual outputs take the form of objects. These can be images, text fonts, templates, and overlays, as well as specific sounds such as beeps, chirps, etc. As a result, image content can be rendered, for example, on a line-by-line basis (at 1/16th pixel resolution), instead of pixel-by-pixel, which is far more data intensive.

Object-Based System

The novel object-oriented approach (which stems from the advanced graphic controller IC at its center) eliminates the need for a frame buffer or a large memory resource for storing image content. Furthermore, it permits the specification of a lower-end, less-expensive, 8- or 16-bit microcontroller. This markedly reduces the system’s component count and board space. The approach also shortens development time, diminishes allocated engineering resources, and ultimately decreases overall project investment. The microcontroller specified for this circuit is a low-cost ATMEG328P on an Arduino Pro board; the application was developed via the free Arduino toolset.

The object-based graphic control element of the system, the FT801, comes from FTDI Chip’s Embedded Video Engine (EVE) series. It has exactly the same key properties as its sister product the FT800, but suits capacitive rather than resistive-touch operation. All that’s required is to connect a standard capacitive-touch controller to the FT801 via its I²C interface and integrate the touch protocol. Subsequently, the position of up to five individual touch points can be simultaneously determined, which in turn makes it possible to benefit from even the most sophisticated of user gestures. The IC’s sophisticated hardware engine can recognize touch tags and track touch movement, delivering notification of up to 255 touch tags.

Capable of supporting WQVGA and QVGA format displays (with resolutions up to 512 x 512 pixels), the FT801 supports 18-bit RGB color with 2-bit dithering for improved color tone. Running off a single 3.3-V supply, the device comes with different objects preloaded on to its embedded ROM. Various sounds and fonts are included to create greater flexibility and scope for real differentiation in HMI designs. In addition, incorporation of alpha-blending and anti-aliasing features help enhance image quality. An audio output built into the FT801 can be connected to an external speaker.

Summary

The operational advantages of capacitive touchscreens, which beget compelling user experiences, will certainly lead to the touchscreens’ wider proliferation. Well-informed design decisions and sourcing of advanced ICs will produce efficient capacitive-touch HMIs with better touch performance, as well as offer the prospect of including multi-touch functionality. The circuit in Figure 2 shows that by adopting an approach that deals with images and sounds in the form of objects, rather than in the traditional, data-heavy method, can bring a form of HMI “shorthand” into play.

The emergence of systems using the latest generation of graphic-display-controller ICs need fewer peripheral components and rely on low-bandwidth interfaces. These innovations will bring about HMI systems that can push the technological envelope with minimal logistical and financial impact.

About the Author

Gordon Lunn

Global Customer Engineer Support Manager

Gordon Lunn is the global customer engineer support manager at FTDI Chip. He graduated from Heriot Watt University with a BEng (Hons) in electrical & electronic engineering and has 15 years of industry experience. Previously, he worked for Racal Defence and IndigoVision in digital design.